Unlock System 550's Full Potential

System 550 is a next-gen modular control system that integrates temperature, humidity, and pressure regulation with industry-first A2L refrigerant leak detection. With optional two-way cloud connectivity for real-time monitoring and alerts, it’s the ideal HVAC-R solution.

System 550 is a powerful, multi-stage control solution that seamlessly integrates temperature, humidity, and pressure management with plug-and-play compliance for A2L refrigerant leak detection and mitigation.

- Built on over 105 years of proven PENN technology, it delivers unmatched reliability for critical applications.

- Offering exceptional power, versatility, and value, System 550 sets the standard for modular electronic controls.

Smart Modular Control with Built-In A2L Leak Detection & Cloud Connectivity

New & Evolving Regulations

There is pressure when it comes to meeting new government refrigerant regulations, but finding the time, resources, and expertise to ensure compliance can be challenging.

System 550 is designed specifically to address and meet A2L refrigerant regulations through an advanced A2L refrigerant leak detection and mitigation solution.

Multiple Control Parameters

Operating and maintaining multiple controllers is costly, time-consuming, and inefficient, stretching your team and resources.

PENN System 550 integrates multi-stage temperature, humidity, and/or pressure control with A2L refrigerant leak detection and functionality into one efficient, easy-to-use system.

Minimizing System Downtime

Every minute your system isn’t operating properly, it directly affects your bottom line and the quality and safety of your products. In short, you can’t afford a system that doesn’t perform.

Designed with advanced features and system alerts to catch issues early, PENN System 550 provides unmatched performance, user-friendly operation, and reliability to reduce product loss and provide occupant comfort and productivity.

A2L Refrigerant Leak Detection & Mitigation

Comply with the newest A2L refrigeration regulations while fulfilling multiple control needs, including temperature, humidity, and/or pressure.

A Simple, User Friendly, and Intuitive Solution

A simple menu makes it easy to configure a C550 control module to meet your application needs.

Cloud Connectivity and System Alerts

Monitor your system remotely with alerts and change configuration settings with Controls System Cloud.

High Performance and Ensured Reliability

Maximize equipment uptime and optimize system efficiencies.

Unlock System 550’s full solution with our multistage controller and A2L refrigerant sensors — all connected through Controls System Cloud.

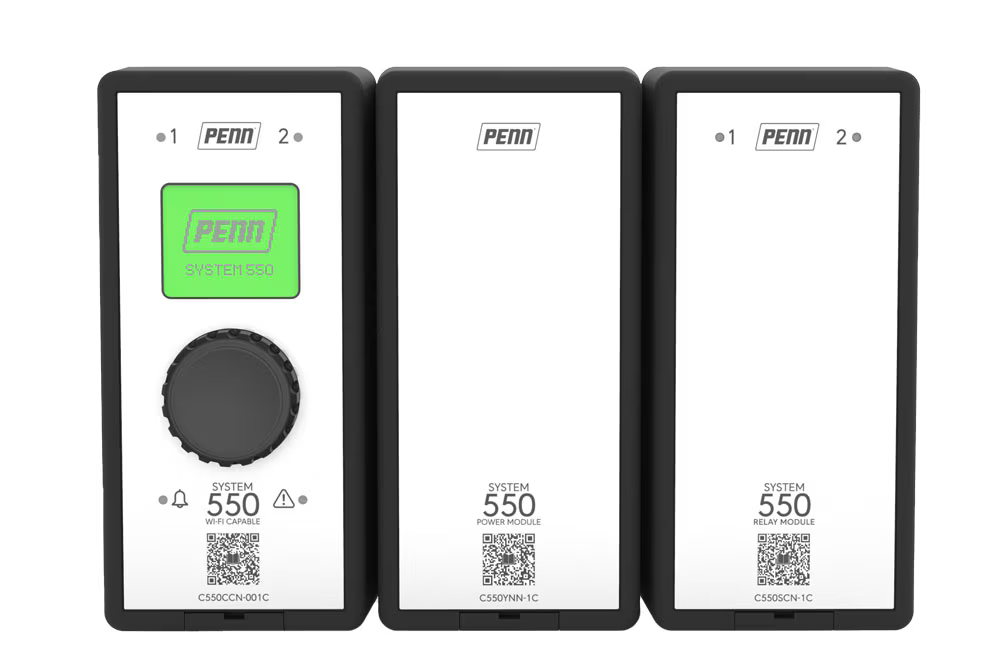

Multi-Stage Controller

A2L refrigerant leak detection and mitigation

Controls System Cloud

- Temperature, humidity, and/or pressure control supports a range of HVAC-R applications.

- Modular electronic control system allows up to 3 temperature, humidity and/or pressure sensors in any combination, along with 10 relay and/or analog outputs.

- Enables informed decision-making to optimize system up-time and occupant comfort and safety.

- Plug-and-play A2L refrigerant leak sensing and mitigation control solution that gives you confidence in meeting regulation deadlines.

- Speed-of-sound A2L refrigerant sensor technology provides the fastest response time on the market <7 seconds (T25) and a warm-up time of <5 seconds, making it easy to meet international standards

- A2L refrigerant sensors communicate with the C550CCN control module via Modbus, making it easy to identify which sensor detected a refrigerant leak or a sensor fault.

- C550CCN control module supports up to 6 A2L refrigerant sensors.

- Modbus provides A2L sensor end-of-life notifications, preventing unnecessary system downtime.

- Provides remote monitoring of HVACR system health from any where in the world, along with the ability to change menu settings, and review and/or download trend data to assist with troubleshooting.

- System data can be used to prioritize and potentially eliminate the need for some service calls.

- Trend data can be used to pin-point system related issues, allowing preventive maintenance to be performed.

-Operates under the highest level of cybersecurity protocols to significantly reduce cyber-attack risks.